Layering clay on original dummy cover to proposed design style. |

Finished clay design model.

Design & Clay modelling time: 80+ hours. |

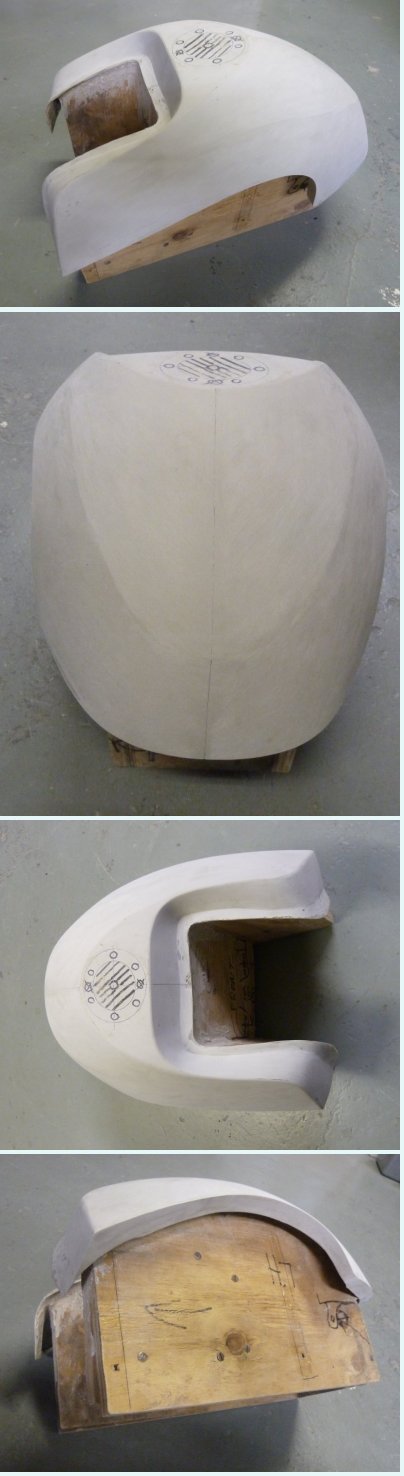

Shuttering placed around part top model and gelcoated. |

Layered glass on top mold, and trimmed, and start building wood support frame. |

Turn mold over and stripped off edge shuttering, clean up, wax up to make mold edge trim lay up. |

Original dummy cover and clay model removed and clean up mold face, mold edge trim replaced to gel up mold then glass layered for final tool. |

Tool (inside mold) left to set, then wood stand/base made and resined in place, edge trim removed ready for parting mold. |

Tool removed from mold ready for clean up and checking/finishing. |

Finished hard resin tool ready for tinsmiths to form rolled steel onto.

Tool manufacturing time: 70+ hours

Now we can start making a tank! |

Original dummy cover shot-blast ready for tinsmiths to mate within new skin/steel made from above form tool.

Finish tank pictures soon to follow. |

|

|

The Making of the 'Tour-Star' (1.3 Gallon / 6 litre) Extra Fuel Tank © Exactrep 2013